We have also recently started a program where people who are not clients of ours can get 3D models of their ideas made by us at the MakerLab for a fee. This being a free service for current clients.

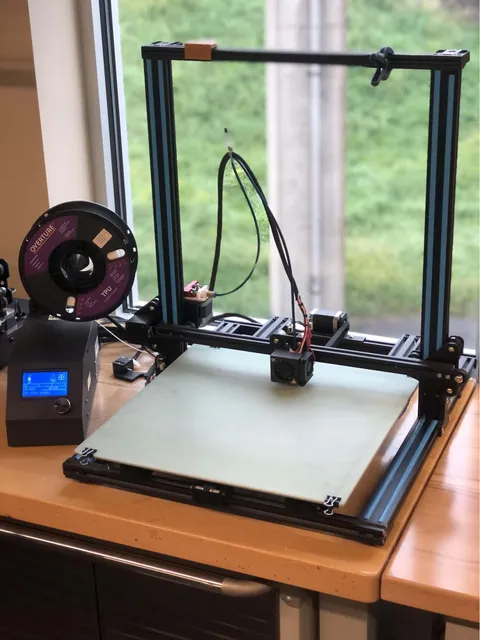

MakerLab is a modeling space for students who are interested in

learning how to build a 3D model of their innovation. Students of all disciplines who

are LaunchLab clients can work with engineering partners to design, build and test

their inventions. Students can schedule an appointment with MakerLab staff in order

to be trained on all equipment use.

Makerlab FAQs

-

Does it cost anything to create a model?

No, as long as you are a client of the WVU LaunchLab.

-

Do I need to be in an engineering degree track to use the MakerLab?

No. All students no matter their degree can utilize the MakerLab and the LaunchLab once you are a client.

-

How can I trust that my idea will not be stolen?

All MakerLab and LaunchLab employees sign Non-Disclosure Agreements that prohibit them from discussing your ideas outside of the labs.

-

May I use MakerLab equipment on my own?

Yes, if a MakerLab engineer is present.

-

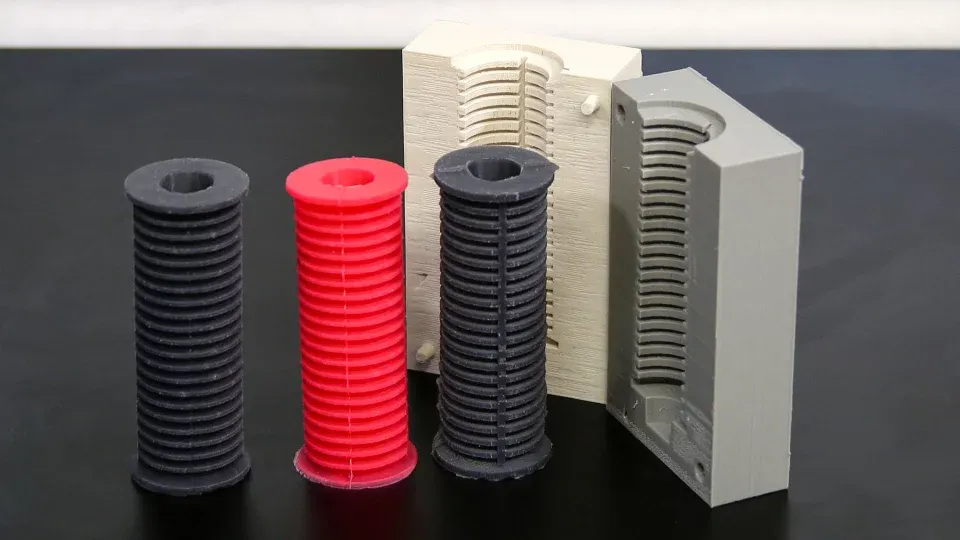

How long does it take to 3D print a prototype?

Depends on the size of the object but generally one to two days. But, make sure to review your client agreement with the MakerLab staff so that you understand the terms and timeframe.

-

What if I have an idea, but am not sure how to proceed? Can the MakerLab help?

No. But the LaunchLab can! Then if a product is the result of your idea, the MakerLab can assist with the model.